On 3rd of March, the Asiamold(Guangzhou international mould exhibition) which was covering the area of moulding manufacturing, 3D printing, laser manufacturing and metal forming technology was successfully opened in the exhibition hall of China import and Export Fair in Guangzhou. More than 650 enterprise had involved in the exhibition and presented themselves in 130 topics in the five pavilions to share the latest information in industrial automation, mould manufacturing and 3D printing industry, and focus on technical achievement as well.

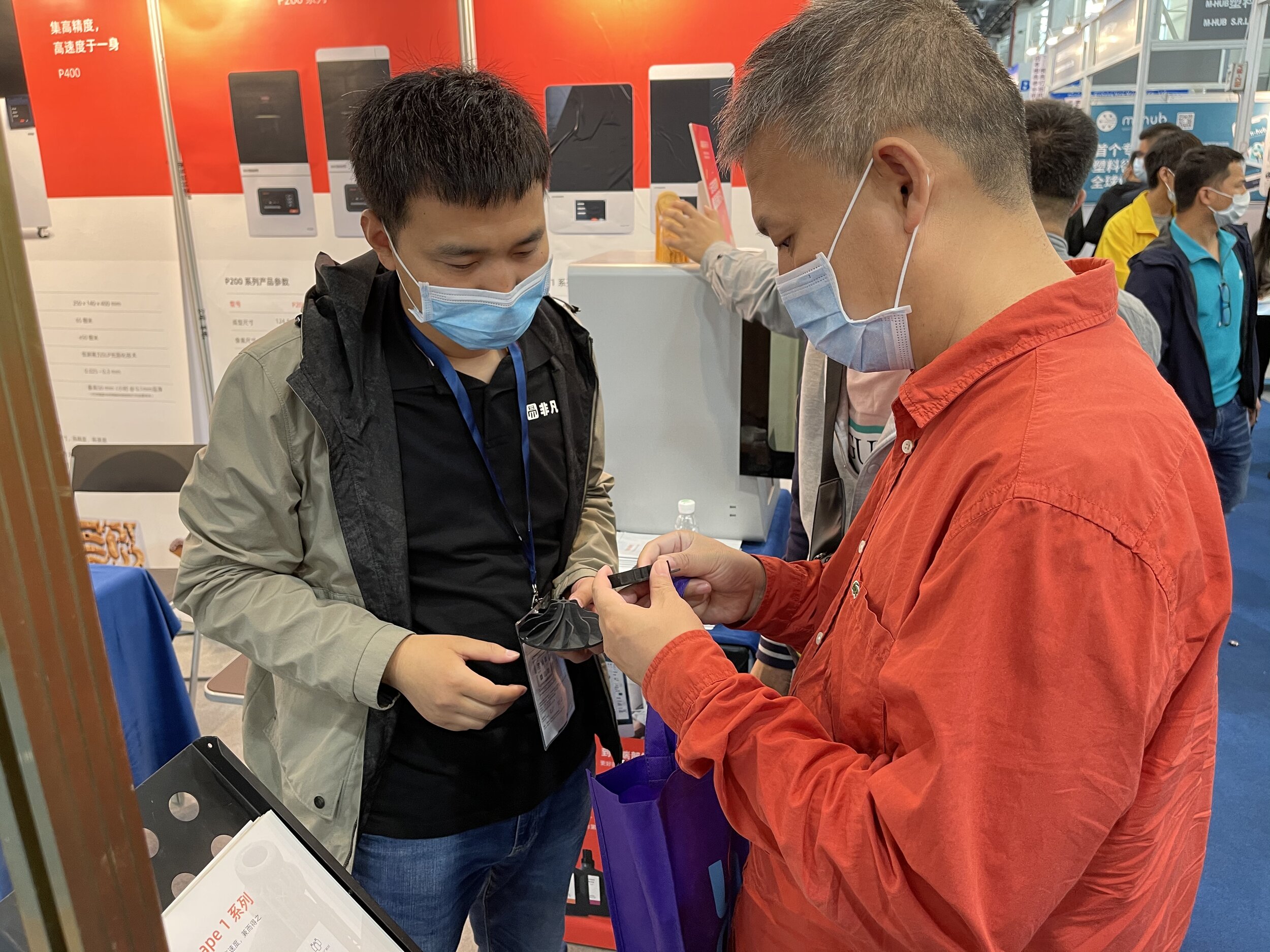

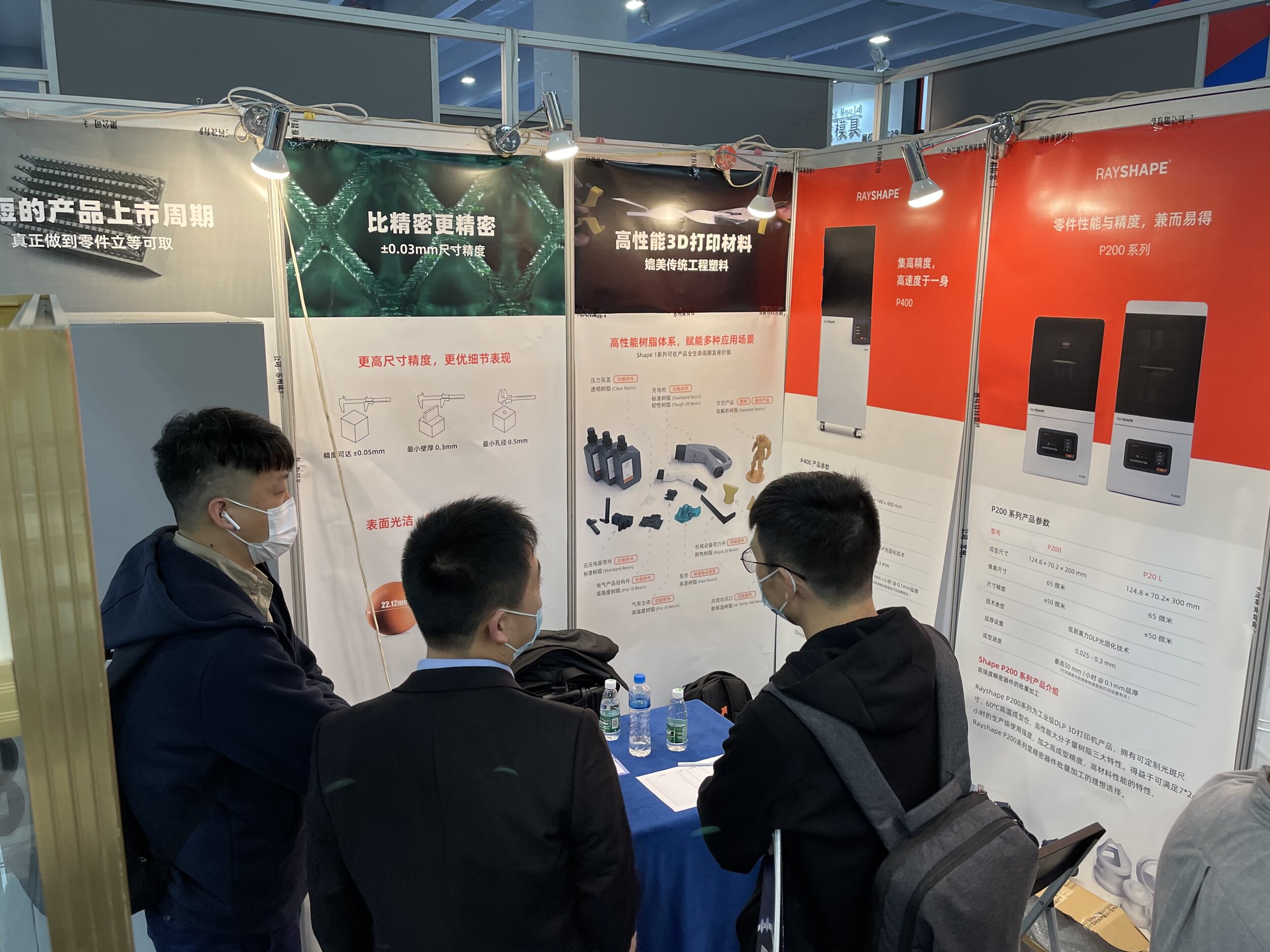

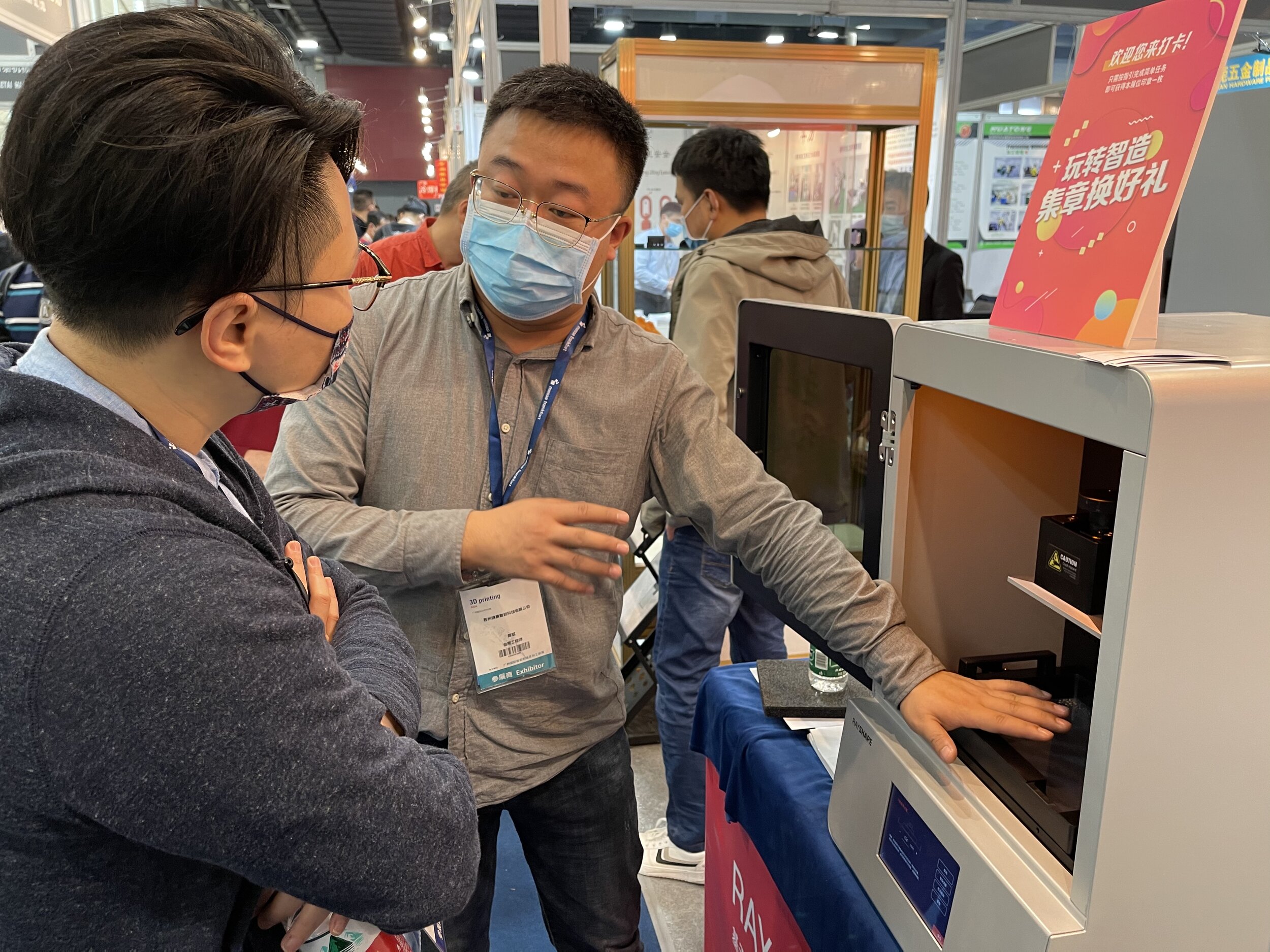

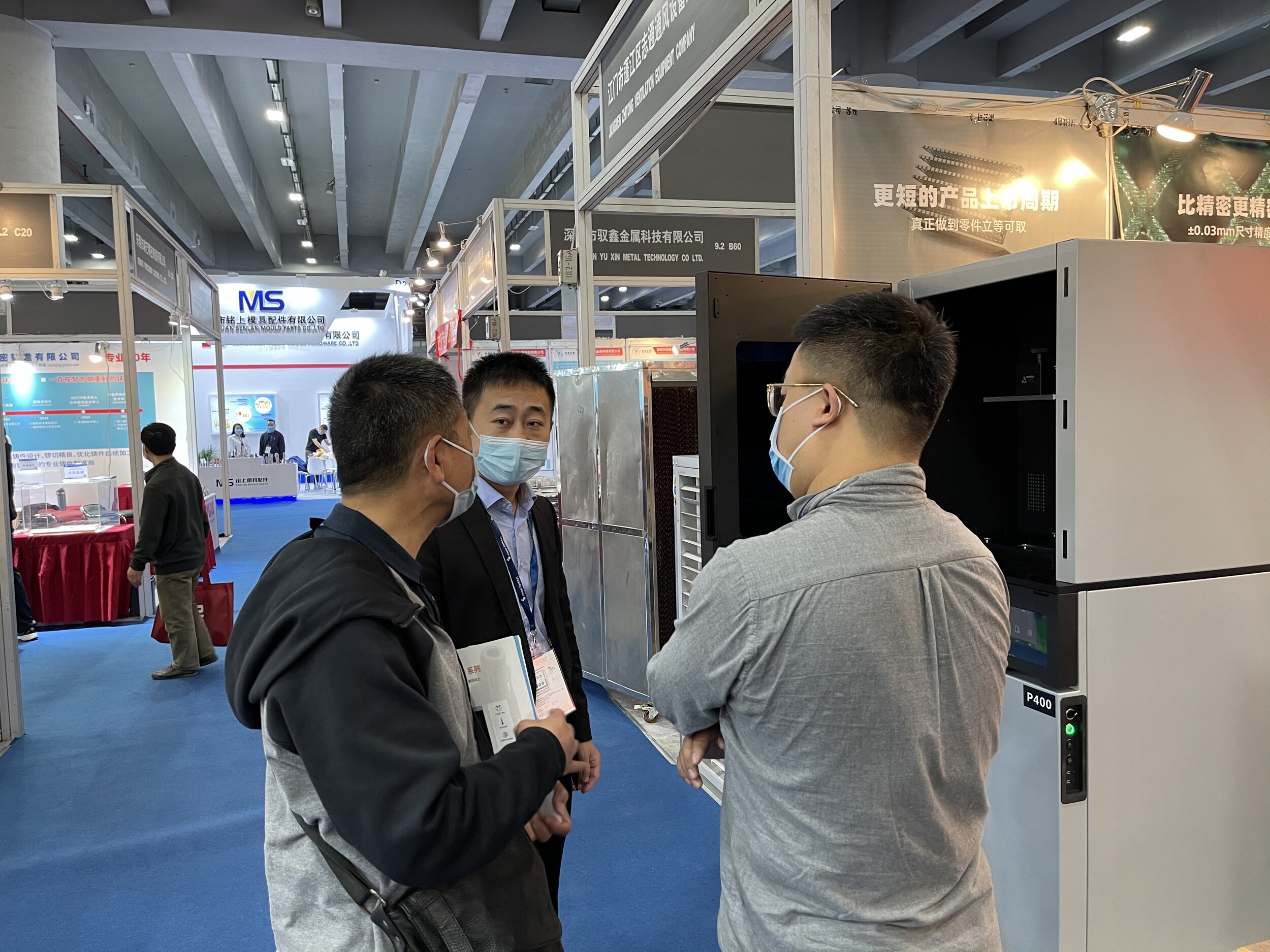

As the exhibitor of this exhibition, Rayshape show the high performance desktop and production level 3D printer to the audience in Hall 9.2 which was located in Area B. The outstanding performance of 3D printer and resin material of Rayshape was shown by lots of precised printouts in the mean time.

As a provider of digital production solution based on 3D printing technology, Rayshape showed Shape 1 HD(desktop level) and P400 series(production level) in the exhibition, then provide strong support in the application area of industrial design, industrial production, mold development, education, medical research ,consumer electronics and cultural and creative arts.

About Shape 1 HD

Shape 1 HD which was one of the main product of Rayshape was a desktop level equipment using DLP technology. The printing speed of Shape 1 HD was almost 50mm/h even 10 times faster than that of the ones which was using SLA technology.

Shape 1 HD

High performance DLP optical mechanism which was with DMD chips and imported high quality LED light source was applied in Shape 1 HD already. Comparing with 3D printer with LCD technology, the core optical system of Shape 1 series was much reliable with service life time over 30,000h , thus downtime which was generated by maintenance task was reduced accordingly.

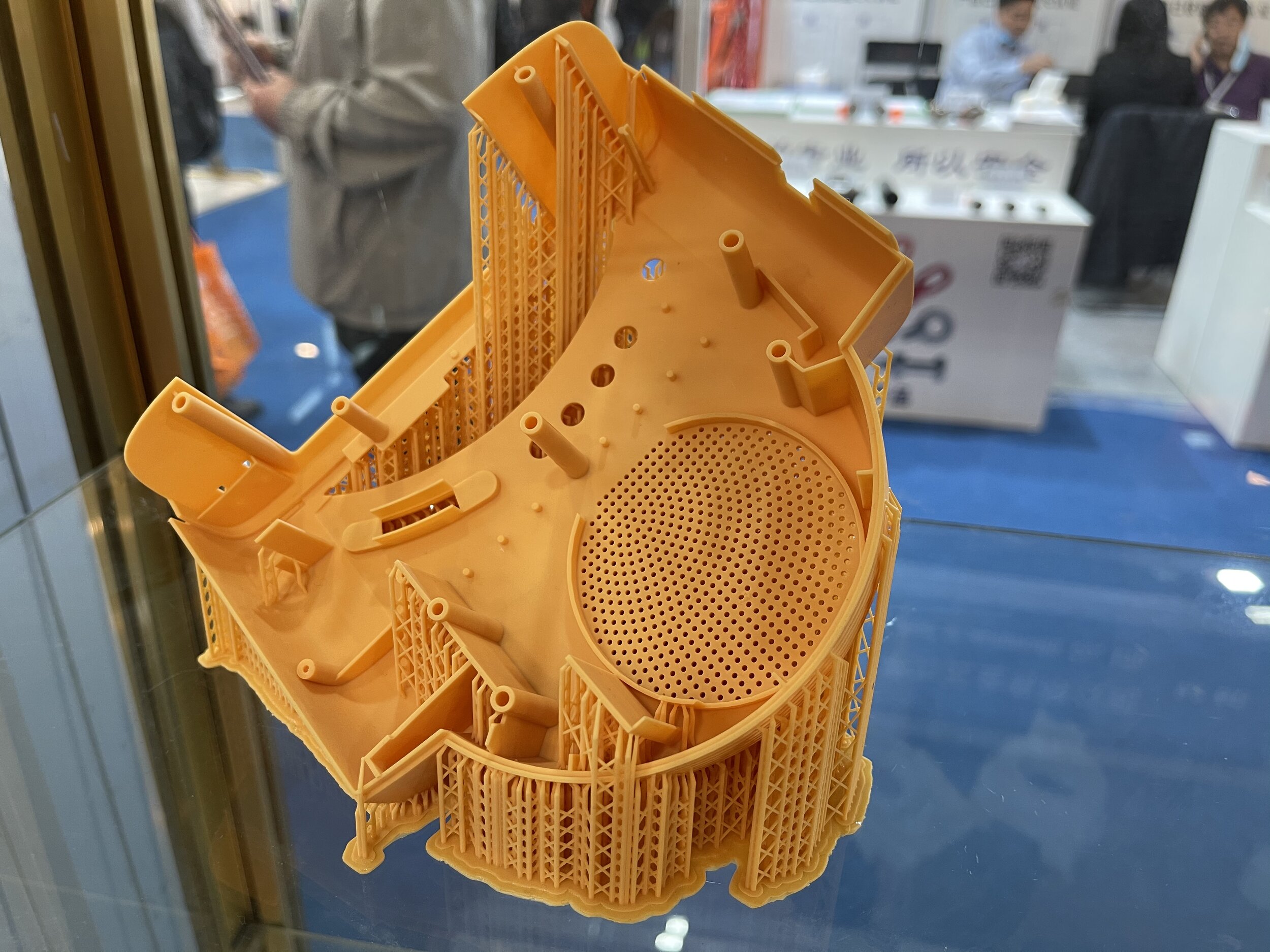

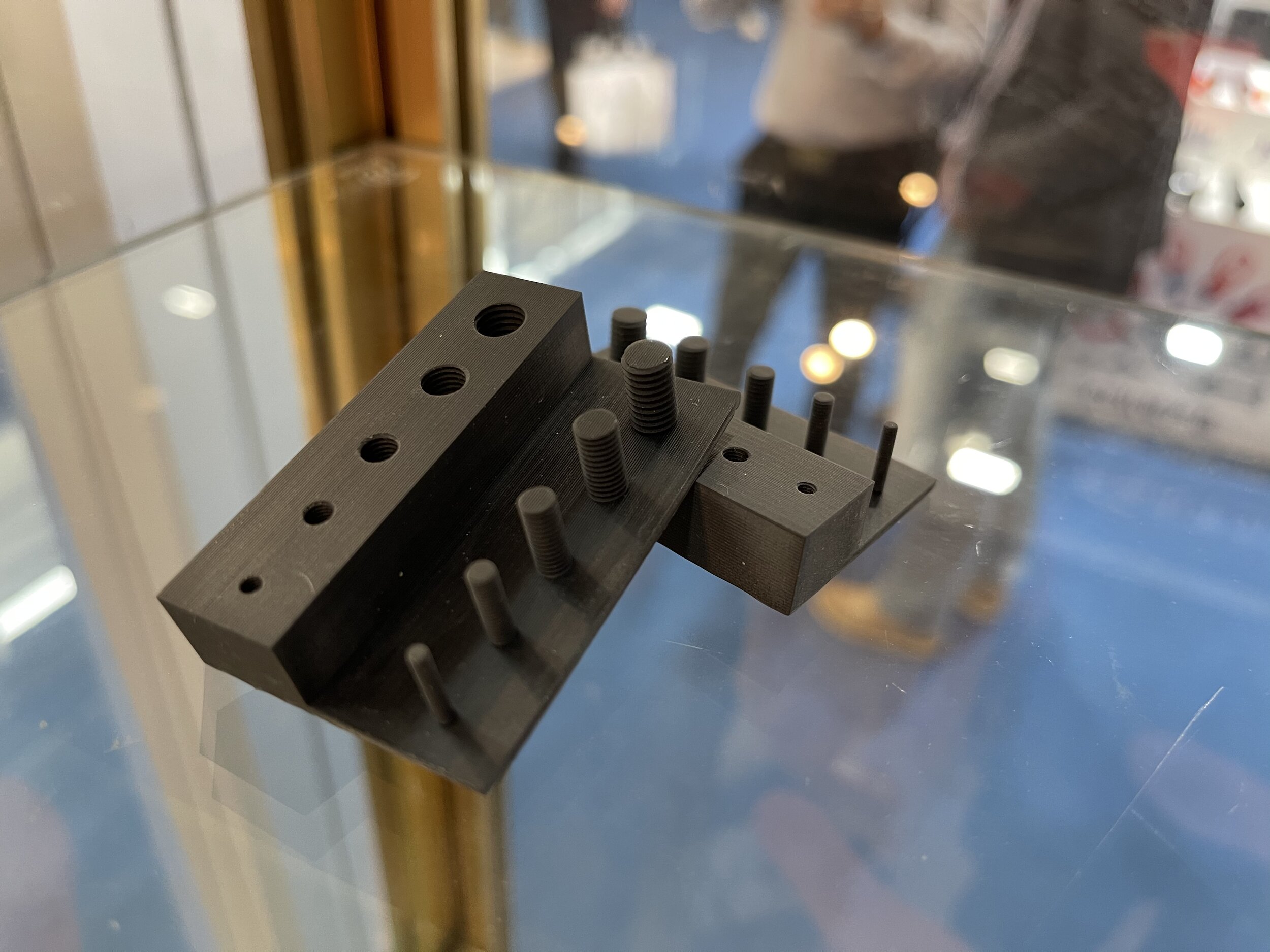

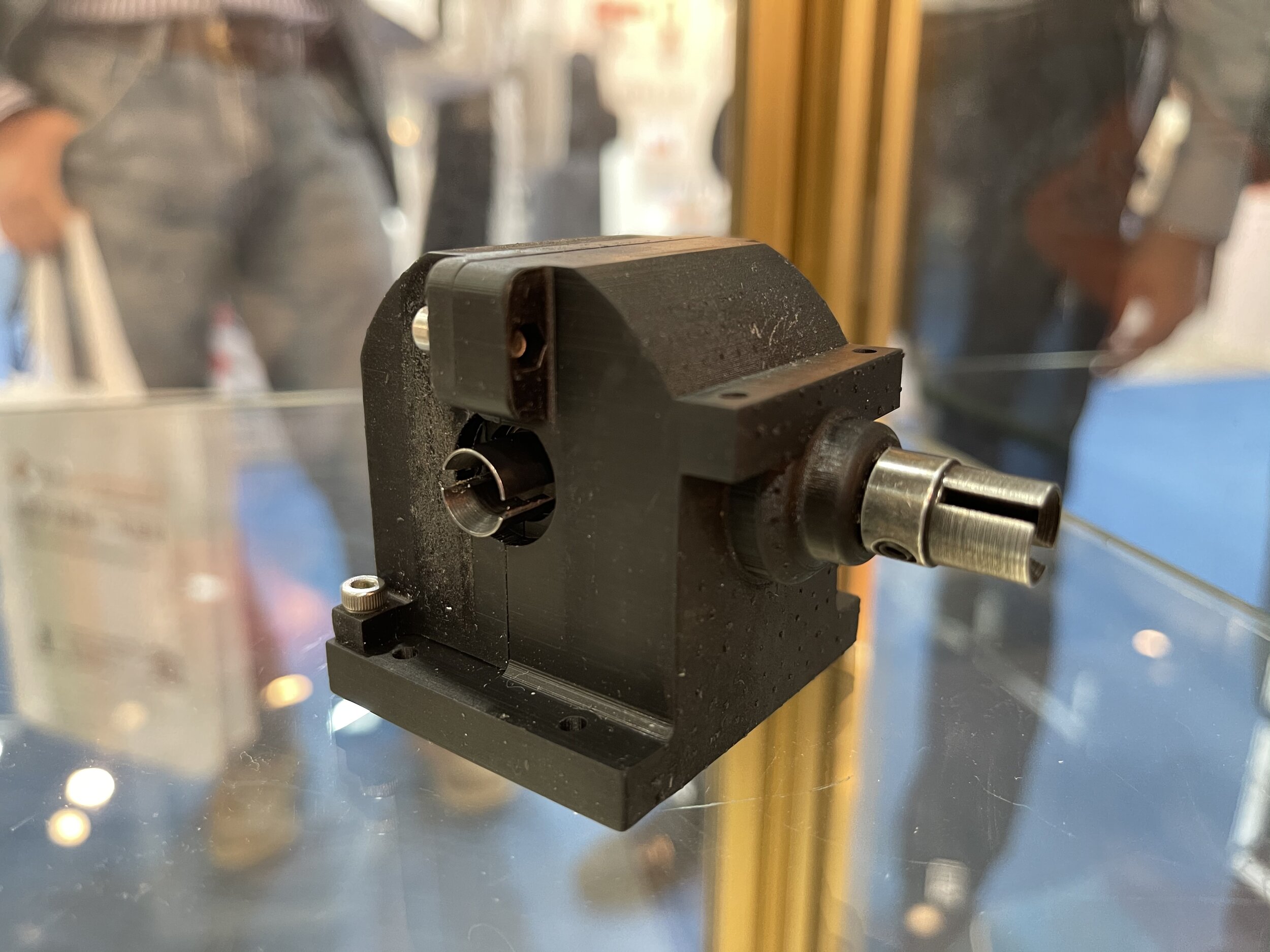

All the high performance photosensitive resins which were matching with Shape 1 HD series were characterized by high comprehensive mechanical performance including high strength, little deformation and dimensional stability. Then they are allowed to be used for not only prototype production for appearance verification, but also printing of functional component, manufacturing of fixture and as well as production of spare parts.

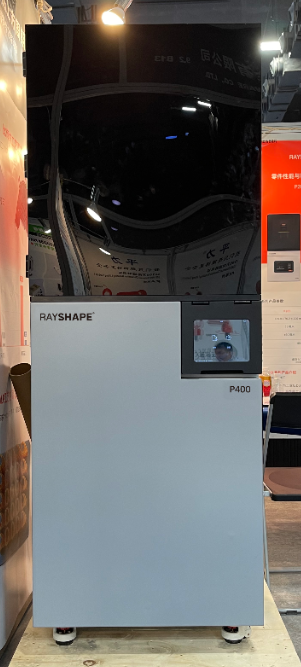

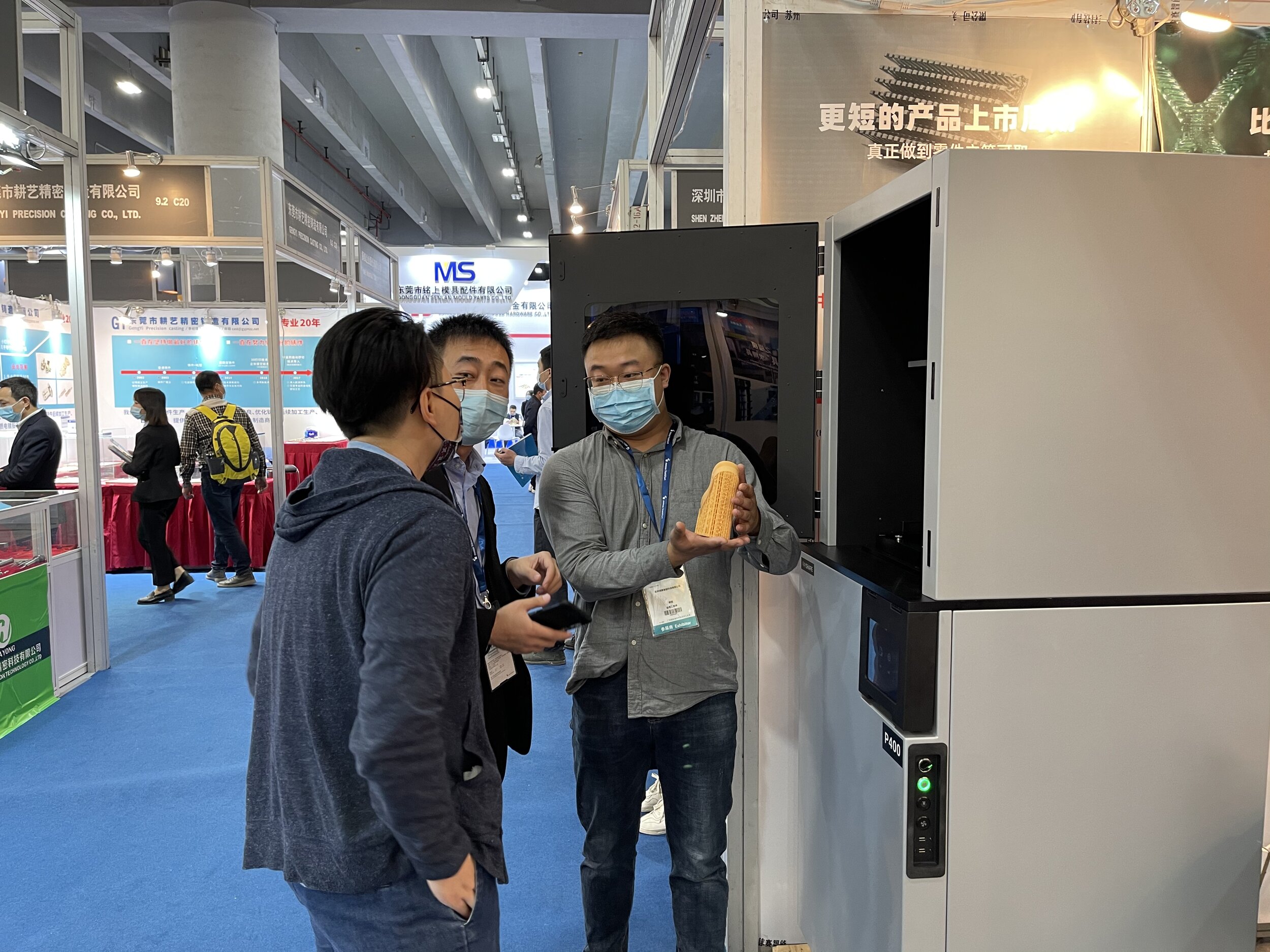

About P400

Another equipment which was exhibited by Rayshape was P400 series. P400 series could be a total customized design that the spot size can be customized between 32.5μm and 65μm, thus achieving an excellent performance in some application area (Cultural and creative, electronic connector and so on)that extraordinary precision and good quality in surface was required.

P400

The main features of the imported optical machine which was applied in P400 series were as follow:

Ø Minimal distortion

Ø High light uniformity

Ø Low light attenuation

Ø 4 times of molding size

Ø Withstand the workload of 7*24h

Thus it could fulfill the requirement of mass production accordingly.

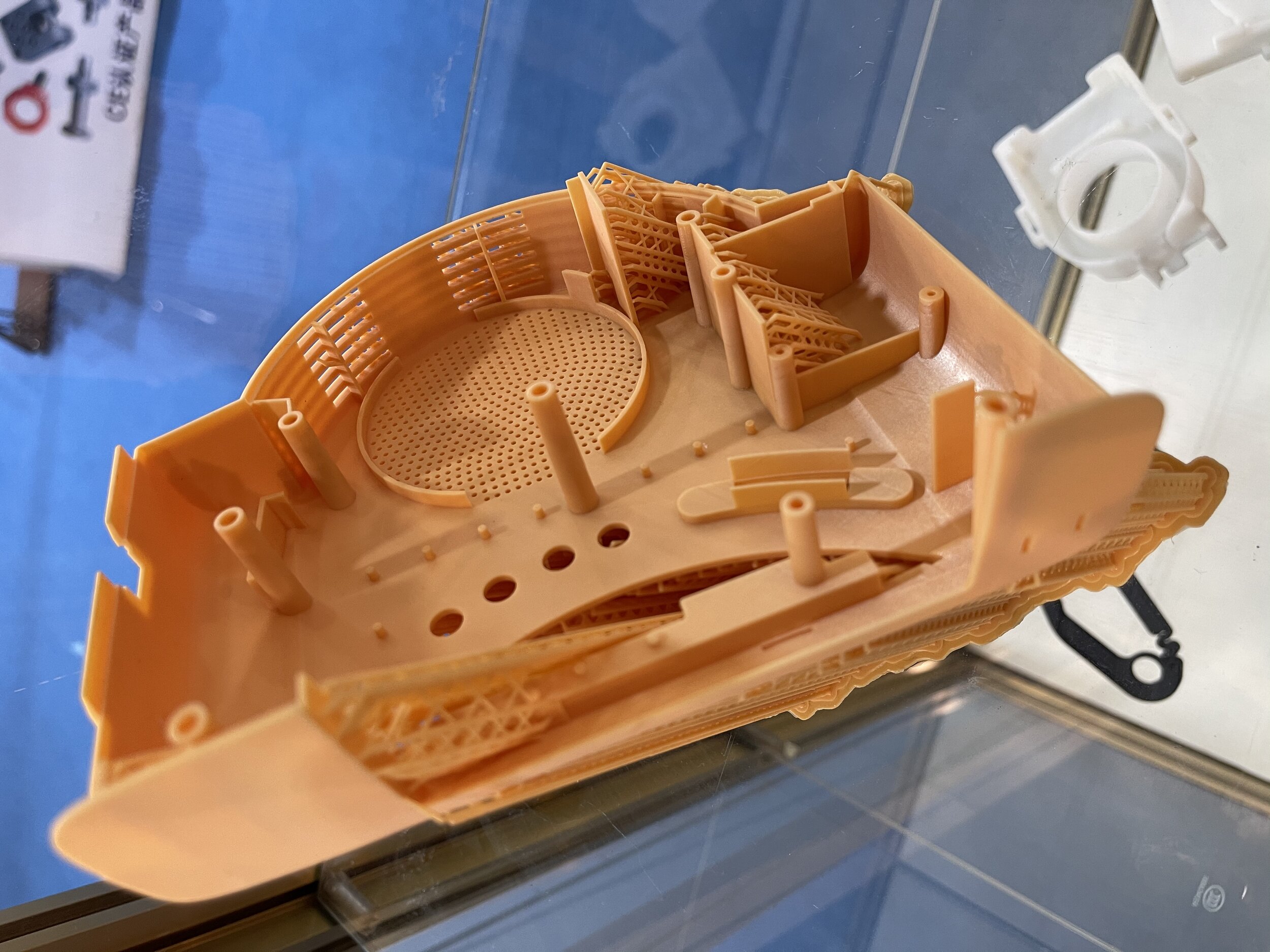

About the high performance resin

It is worth mentioning that many visitors are very interested in high-performance material of Rayshape, and many topics which was related to special application scenarios of high performance material were raised up by them accordingly. It seems that functional series of photosensitive resins are favored by many visitors.

Functional series of photosensitive resins

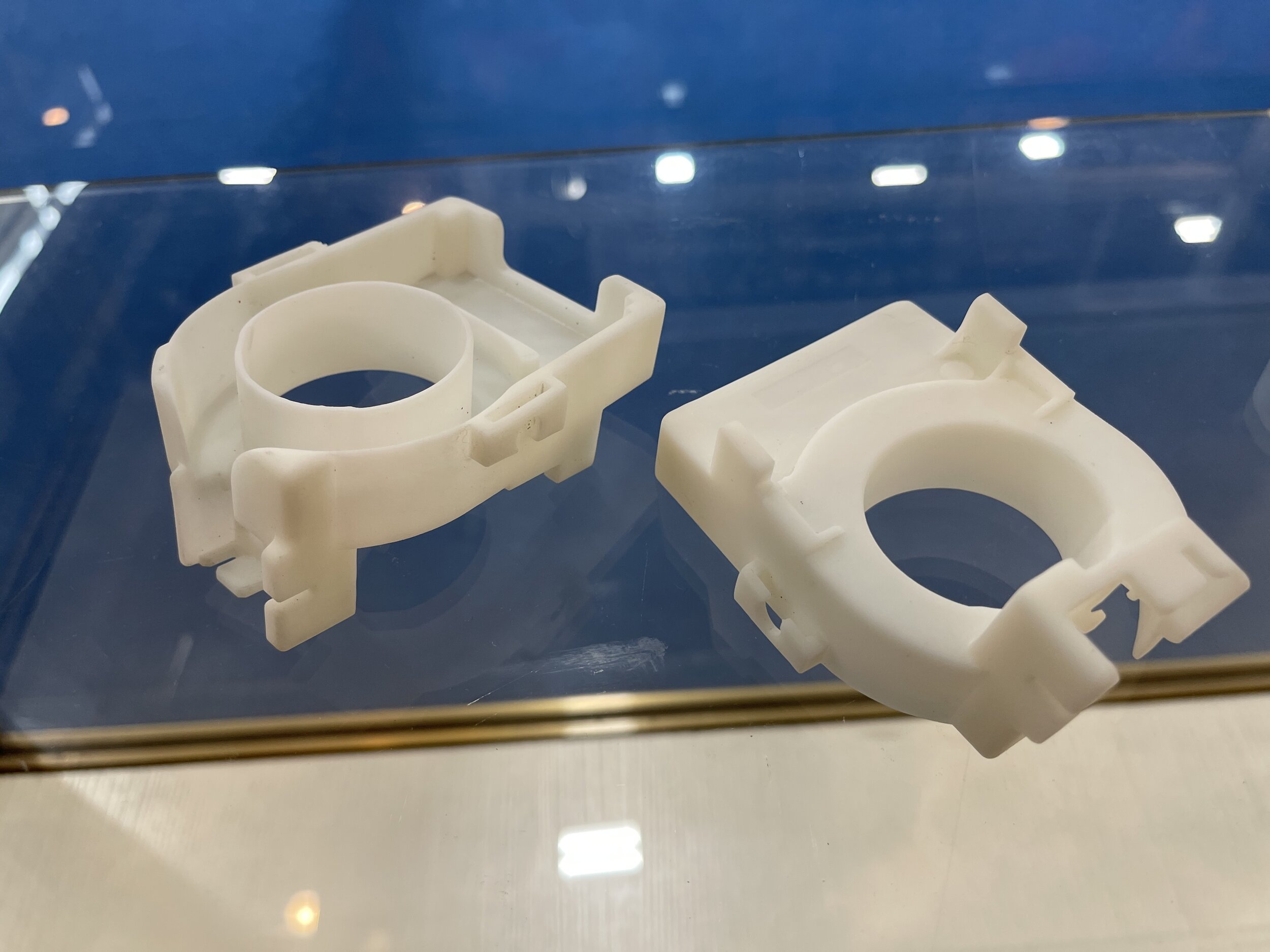

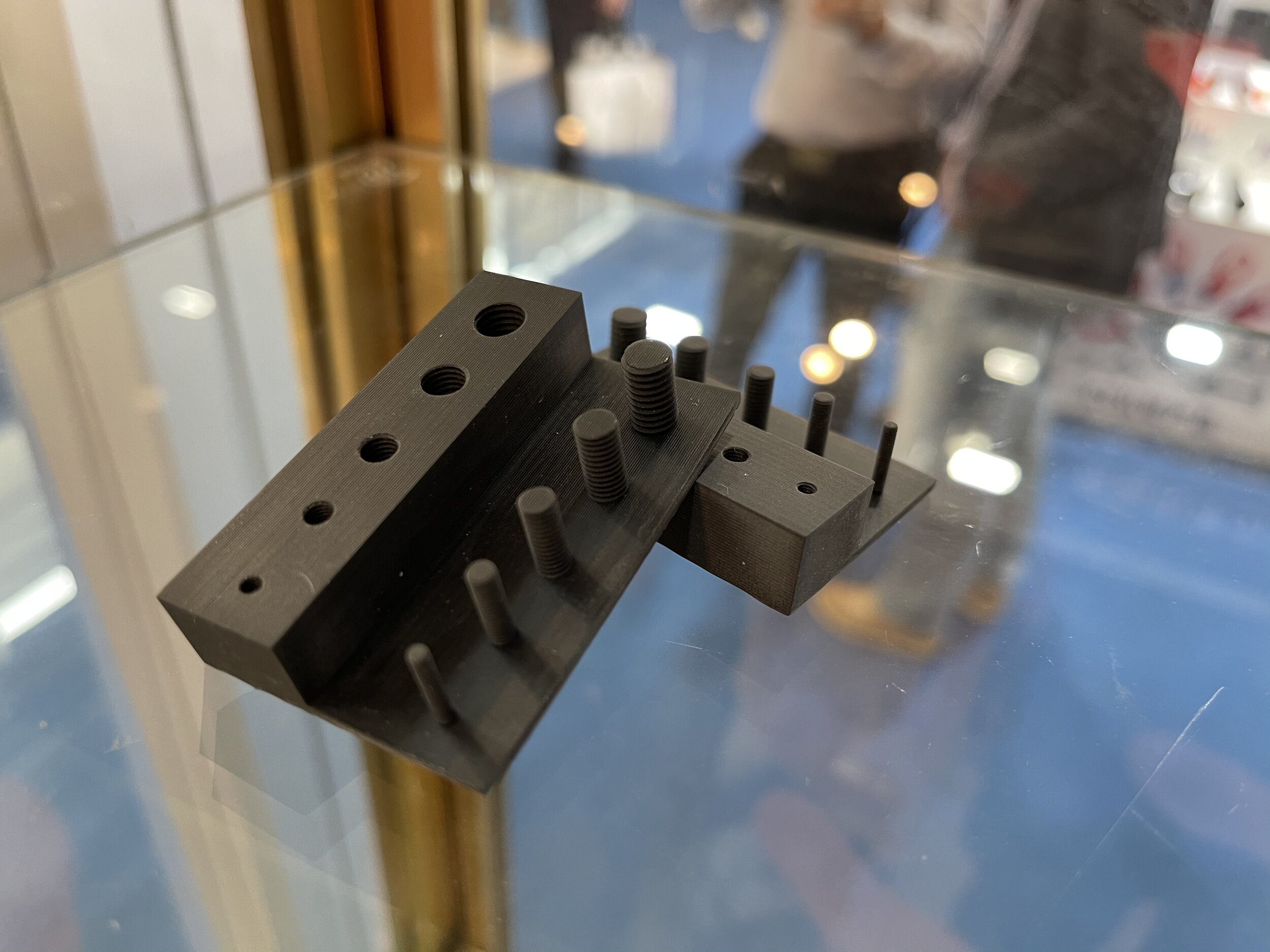

Functional series of photosensitive resins are including tough resin (black and white) / tough 20, rigid resin / rigid 20, high permeability resin / clear, high temperature resistant resin / High-temp 160, red wax resin / Red-HD, high strength resin / Pro 10.

Tough 20 is a resin material with main features of high toughness,high elongation at break and impact resistance. It is much suitable for application scenario of functional prototype, and verification case that certain mechanical requirement was needed.

Rigid 20 was a resin material which was characterized by high stiffness, high hardness and low creep fitting for application scenario with requirement of certain stiffness. But the impact resistance of that was poor a little bit.

The performance of high-strength resin por 10 is between that of tough 20 and rigid 20. It has a balance performance with regards of toughness and rigidity, and characterizing by low creep as well. Thus It was allowed to be used for functional prototype production that high strength was required.

Hi-Temp 160 resin was a kind of high temperature resistance material. It could achieve the desired effect of 160 ℃ HDT without post-heat curing. But the material was brittle and with low performance of impact resistance.

High transparent resin is a kind of resin material with high transparency especially with the treatment of fine grinding and oil spraying.

Red wax resin is a model resin with excellent performance in expression of detail. It is the best mold material for high-end handmade and trendy play due to the simple access to fine texture and smooth surface. The printed parts with red wax resin can be used for mold turning over or customized final product.