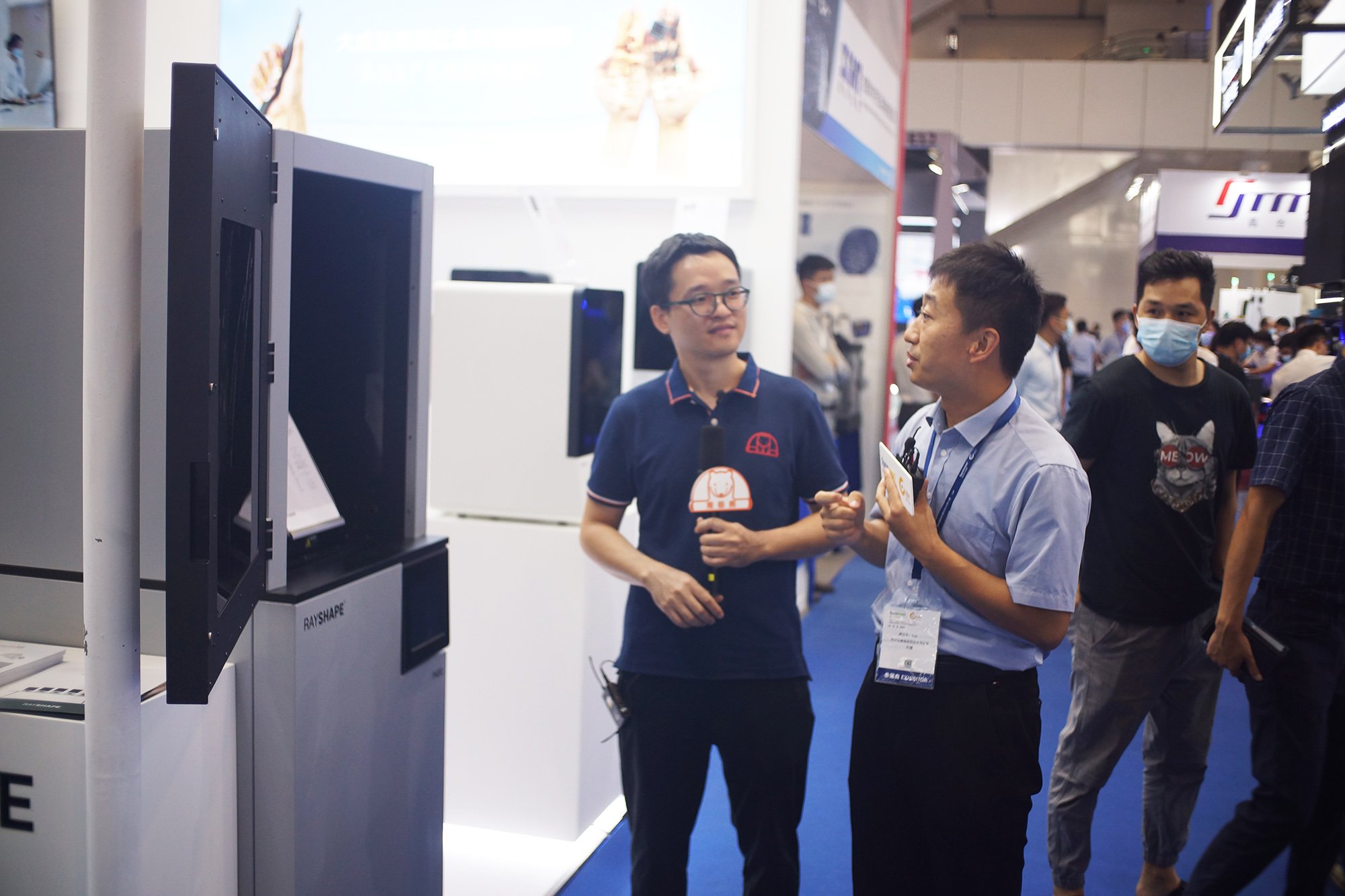

A startup that is gaining momentum in the 3D printing industry

Zhen (Bill) Liu founder of RAYSHAPE

RAYSHAPE provides comprehensive 3D printing solutions. Research and develop 3D printers, software, and resins. Also, manufacture 3D printers.

The company built an open and easy-to-use 3D printing solution that enables professional designers, engineers, and non-specialist to innovate.

Founded by Bill Liu in July 2019, who used to work as an R&D director in UnionTech for six years and driven by a team of talented people with over ten years of experience and deep knowledge of the 3d printing industry, RAYSHAPE has accomplished sales of over 1000 3D printers and accumulated investment of over 10 million US dollars after two years of its establishment.

After approximately two years of development and testing, the first-generation product Shape 1 Series was released in April 2020.Photo of Shape 1 Series including: Shape 1, Shape 1 HD, Shape 1 Dental, ShapeWash Series and Shape cure

Dental 3d models printed with Shape 1 Dental

In 2020 and during the COVID-19 period, RAYSHAPE put the focus on the China mainland market. With excellent product reliability, open, easy-to-use solutions, and advanced 3D printing materials, the startup got the attention in dental clinical applications. The Shape 1 Dental, a favorite 3d printer for clients like DENTAL DOCTOR, ARRAIL DENTAL, TAIKANG BYBO DENTAL, accumulated sales to be the first shipment volume of a dental clinic in 3 quarters.Besides the dental solution, RAYSHAPE also has industrial solutions. In 2020, the startup released Basic and Functional Series Resins. According to the feedback of the customers, the materials have a high performance in many vital indexes: mechanical strength, low shrink rate, high-temperature resistance, toughness, stability over time which gives an advantage to RAYSHAPE in industrial applications, especially in the precision component 3D printing field.In 2021, RAYSHAPE invested more in industrial applications and launched the P400 industrial-grade 4K DLP 3D printer series and Shape 1+ Series products. As for the materials, they released Advanced Series industrial resin, E-ABS 10, for direct manufacturing end-use parts. The P400 attracted considerable attention, and clients like HUAWEI, UNITED IMAGING, STANLEY, Harman Kardon and TINNO, purchased the P400 for the 3D printing precision functional parts. Tsinghua University, Peking University purchased the P400 for researching cutting-edge topics. Schneider Electric workshop in Shanghai using Shape 1 HD

In addition to the advantages of its accuracy and speed compared with SLA technology, another factor that attracts these customers is the excellent material performance. The Functional Series Resin shows the advantages of reproducing fine features such as thin walls, narrow slits, and deep holes. It also provides characteristics like high toughness, low shrinkage, and high-temperature resistance to ensure accuracy.A set of sample photos of precision component

Some of RAYSHAPE clients

In early 2021, RAYSHAPE launched a plan to open up to other markets. A lot of work it's been done in product internationalization, technical support, product policies that got positive feedback from some overseas resellers. As a result, now officially opening up to have more partnerships in other markets. Agents and resellers interested in adding high-performance DLP product lines are welcome.